LEAN PRODUCTION

Constant improvments, 5S, Kanban, visualisation, elimination of waste, S.M.E.D, standardization, Just-In-Time, streamline and more.

073-803 22 26

Constant improvments, 5S, Kanban, visualisation, elimination of waste, S.M.E.D, standardization, Just-In-Time, streamline and more.

KPIs, root cause analysis, project management, presentations, control boards, automated calculations, current-state analysis, online courses and more.

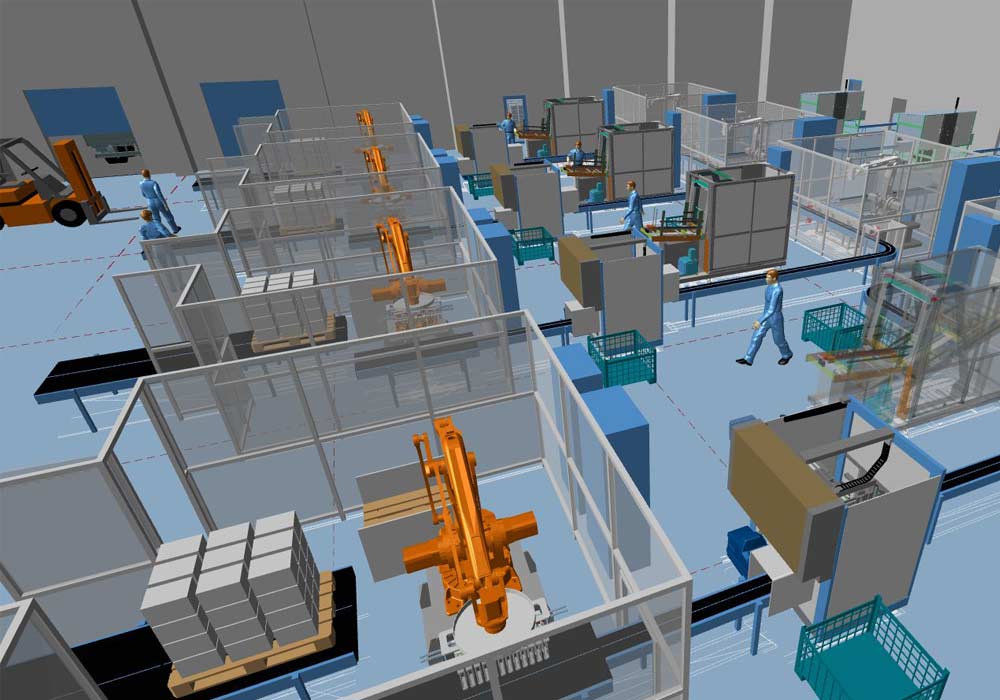

Layout, identifying bottlenecks, quality issues, line balancing, working methods, ergonomics, work instructions, tools, 3D printing and more.

Industry 4.0/5.0, automated workflows with AI, decision basis for automation, procurement and programming of a cobot and more.

We optimize processes to minimize waste and maximize production quality and capacity.

We implement smart technological solutions to automate and improve your manufacturing and operations.